The composite materials have gained more attention during the past decade because of their properties. There are numerous composite materials available for a construction project. Ceramic, wood, or metal composites are some to mention. However, none of these materials have been used more than aluminum composite material sheets (ACM Sheets).

Aluminum composite material sheets are composed of two aluminum layers sandwiched by a mineral-filled or polythene core. The combination of these materials has further helped them to be more robust and rigid. ACM sheets, which were invented in the 1960s, are now one of the most common construction materials worldwide. Their features and characteristics have various usages, which will be explained later in this article. However, for more information about ACP panels, you can visit Aluminum Composite Sheet.

ACM sheets for sale and their price

By looking at various websites, you can easily find ACM sheets for sales; however, these materials’ prices could vary according to their properties. The properties of ACM sheets differ based on client usage. Therefore, when looking for ACM sheets for sale, please pay attention to their price and structural properties. You can also check our other article about aluminum composite panel for sale for more info.

The core:

One critical difference in the ACM sheets properties is their core material. The core elements can have a direct effect on the ACM sheets price. There are mainly two aluminum composite panel cores, although some ACP panel manufacturers can offer their customers more options. Initially, polyethylene (PE) substance was used in ACM panels. This made the panels more flexible and durable. PE aluminum composite panel cores are still used in today’s panels; however, their fire safety rating must be according to the local’s fire safety codes. You can visit PE aluminum composite panel for more info.

The problem for polyethylene ACM sheets core resulted in producing mineral-filled materials that are highly resistant to fire. Most ACM panels now consist of fire-retardant core materials. In other words, you can’t find any aluminum composite panels that start or spread fire anymore. However, this had a direct effect on aluminum composite panel prices.

Coating materials:

ACM sheets consist of various properties. For instance, the protective film protects the sheets from any damage that can affect the sheets’ colors. The coating material is another important structure in aluminum composite material sheets. Most panels have PVDF coating. The PVDF, which stands for Polyvinylidene fluoride, is a special plastic that has the highest purity. This coating material can protect the panels from any possible damage and severe conditions. Other coating elements for ACM sheets are Nano PVDF and PE. The PE coating material is considered the least costly aspect, whereas the Nano PVDF will likely result in more cash from your side.

Even though ACM sheets are considered budget-friendly, you need to know what you get when purchasing them. Aluminum composite sheets have a variety of high-quality features and characteristics, which we are going to explain further below:

ACM Sheets Features:

The popularity of ACM sheets is not due to their cost-effective price and unique elements. Aluminum composite material sheets have various features that are not easy to find in any other construction element.

Color choice:

Before purchasing aluminum composite panels, you can have a variety of color choices. Aesthetics is one of the most critical components of construction projects. That’s why ACP panels can satisfy everyone’s taste. Whether you want a solid color for interior decoration or prefer some customization and textures, aluminum composite panels can cover your needs. For instance, ACM sheets have wooden, marble, mirror, or even metal finishing where you can find more info visit ACP Panel.

Corporate colors are also available with ACP panels. You can use various colors for your corporate or even design and print the logo on the sheets. Most well-known companies have used ACP materials, and more newcomers are also using these panels due to their low cost. As previously mentioned, ACM panels can offer solid colors as well which provides simple designs with the best possible price and attraction.

Durability:

If a purchased construction product can’t last for more than ten years, then the product is not worth it. The same situation applies to ACM sheets. Thanks to their durable coating material and rigid core element, aluminum composite sheets can withstand even the most severe and harsh weather conditions and climates. Moreover, the durability of aluminum composite panel materials means that you can even save more by having the same construction element for years in addition to a low cost.

Flexibility:

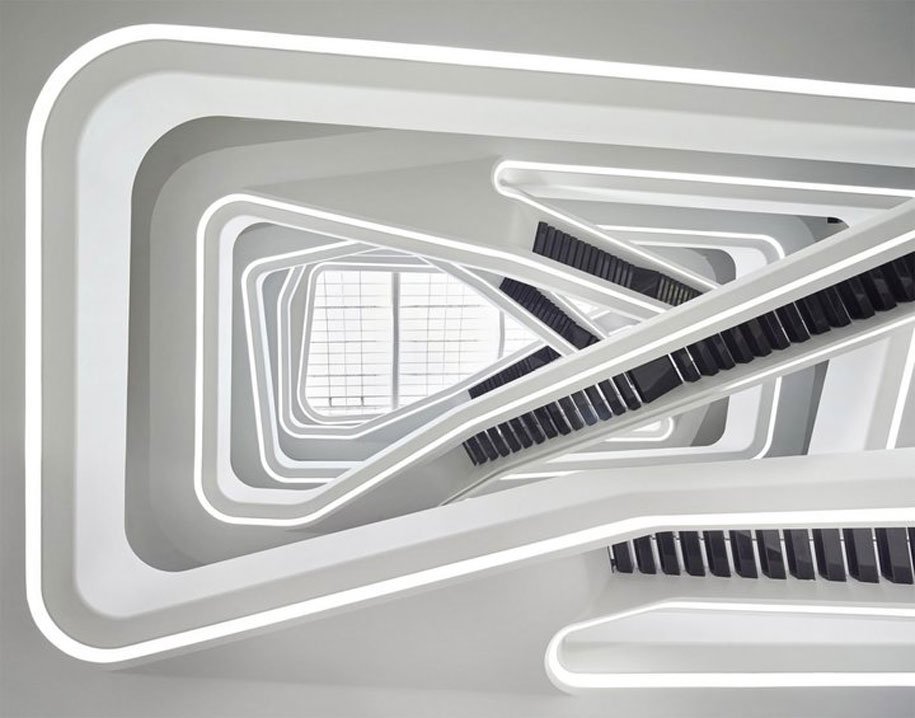

Being rigid and durable doesn’t stop ACM sheets from being flexible. Aluminum composite panels are one of the most flexible construction materials which can be applied even in the most bizarre shapes in cladding and facade. In other words, aluminum composite panels have allowed architects and engineers to design what was impossible a few years ago.

Lightweight:

If we told you that aluminum composite sheet materials have flexibility, durability, and lightweight before this article, you probably wouldn’t believe it. Because of the materials that are used in ACM sheets, these panels have all these features at the same time. The lightweight of these panels has helped them to be used in other industries as well. For instance, transportation and aircraft industries have considerably benefited aluminum composite materials and their lightweight.

Resistance against water, fire, and chemical substances:

One of the most common applications of aluminum composite panel applications is interior decoration. For instance, most custom house builders prefer to use ACP materials in the kitchen because of their resistance against chemical materials.

Though the fire resistance mostly depends on the core, water-resistance extensively depends on your manufacturer. Therefore, ensure that your manufacturer has sealed the panels appropriately since the ACM panel installation is very straightforward. For more information, visit aluminum composite panel installation.

Where can you use ACM sheets?

If we want to answer this question with in-depth details, we probably should write another article where you can visit in ACP sheet. and find more information. However, for now, we suffice to say that aluminum composite material sheets can be used in various applications. For instance, PVDF material coating is mostly used in exterior applications such as cladding, facade, siding, rooftops, transportation, and more. Other applications such as interior decoration, wall siding, false ceilings, and partitions are the aluminum composite panels’ indoor usages. For more information, you can visit Aluminum Composite Material.

The Verdict:

Aluminum composite panels have been around for more than six decades. Even though they were first patented for more than two decades, most suppliers and manufacturers managed to produce these materials after the patent expiration. More than 200 major ACP panel manufacturers are now accessible worldwide, and their number is still growing. You can visit aluminum composite panel manufacturers for more details.

ACM panel sheets have high-quality features and strong structure. Their premium qualities allow for more applications such as external siding and facade, even in the most severe conditions and climates. Moreover, their flexibility offers unique designs where you can fit ACM sheets in any strange shape. All in all, aluminum composite panels can provide excellent features at an exceptional price.

Read more ACM Sheets

I’m not that much of a internet reader to be honest but your blogs

really nice, keep it up! I’ll go ahead and bookmark your website to come back later.

Cheers

I pay a visit day-to-day some sites and websites to

read posts, except this website provides quality based writing.

Have you ever thought about including a little bit

more than just your articles? I mean, what you say is important and all.

But imagine if you added some great photos or videos

to give your posts more, “pop”! Your content is excellent

but with pics and video clips, this site could undeniably be one of the

greatest in its field. Fantastic blog!

I like the helpful info you supply to your articles. I’ll bookmark your

blog and test once more here frequently. I am moderately sure I will be informed lots of new stuff

proper right here! Good luck for the next!

Useful info. Lucky me I discovered your website by accident,

and I’m shocked why this coincidence did not took place

earlier! I bookmarked it.

Wow, amazing blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of your

website is wonderful, as well as the content!

If you wish for to obtain much from this article then you

have to apply such methods to your won web site.

It’s actually a cool and useful piece of info.

I am happy that you shared this helpful info with us. Please stay us up to date like this.

Thank you for sharing.

What’s Going down i’m new to this, I stumbled upon this I’ve found It positively helpful and it has helped me out loads.

I’m hoping to contribute & assist different users like its

helped me. Great job.

Very good information. Lucky me I discovered your blog

by accident (stumbleupon). I’ve bookmarked

it for later!

I love your blog.. very nice colors & theme. Did you make this website

yourself or did you hire someone to do it for you? Plz respond

as I’m looking to create my own blog and would like to find out where u got this from.

kudos

Wow, that’s what I was seeking for, what a information! existing

here at this webpage, thanks admin of this website.

I blog quite often and I seriously appreciate your information. This article has truly peaked my interest.

I am going to take a note of your blog and keep checking for new information about once a week.

I subscribed to your Feed as well.

This is my first time pay a quick visit at here and i am in fact pleassant to read all at alone place.

I am truly pleased to glance at this website posts which includes lots of valuable information, thanks for providing

these statistics.

Whoa! This blog looks just like my old one! It’s on a entirely different topic but it has pretty much the same

page layout and design. Excellent choice of colors!

An outstanding share! I have just forwarded this onto a co-worker who

had been doing a little research on this. And he actually ordered me breakfast due to the

fact that I stumbled upon it for him… lol. So allow me

to reword this…. Thanks for the meal!! But yeah, thanks for spending some time

to talk about this topic here on your internet site.

Hello, i think that i saw you visited my web site so

i came to “return the favor”.I am trying to find things to improve my

website!I suppose its ok to use a few of your ideas!!

Thank you for the good writeup. It in fact was a amusement account it.

Look advanced to more added agreeable from you! However, how can we communicate?

Ahaa, its pleasant conversation about this piece of writing here at this webpage, I have

read all that, so now me also commenting here.

I love your blog.. very nice colors & theme.

Did you create this website yourself or did you hire someone to do it for you?

Plz reply as I’m looking to create my own blog and would like to find out

where u got this from. cheers

Excellent goods from you, man. I’ve be aware your stuff previous to and you are just extremely great.

I really like what you have got here, certainly like what you’re stating and the way

through which you say it. You make it enjoyable and you continue to take care of to keep it wise.

I can’t wait to read much more from you. That is actually a

wonderful website.

Heya! I understand this is somewhat off-topic but I needed to ask.

Does building a well-established website like yours take a large amount

of work? I’m brand new to blogging but I do write in my diary daily.

I’d like to start a blog so I will be able to share my

personal experience and thoughts online. Please let me know if you have any kind of suggestions or tips

for new aspiring blog owners. Appreciate it!

Every weekend i used to pay a visit this web page, because i

want enjoyment, since this this web site conations in fact pleasant funny information too.

Greetings! Quick question that’s totally off topic. Do you know how to make your site mobile

friendly? My blog looks weird when browsing from my iphone4.

I’m trying to find a template or plugin that might be

able to resolve this problem. If you have any suggestions, please share.

With thanks!

Just want to say your article is as amazing. The clearness for your put up is just spectacular and that i can suppose you are

an expert in this subject. Fine together with your permission let me to

seize your feed to stay updated with approaching post. Thank you 1,000,000 and please

carry on the rewarding work.

Everyone loves it whenever people get together and share thoughts.

Great blog, keep it up!

This design is wicked! You certainly know how to keep a reader amused.

Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!)

Wonderful job. I really enjoyed what you had to say, and more than that,

how you presented it. Too cool!

If you wish for to improve your knowledge only keep visiting

this site and be updated with the most recent gossip posted here.

I got this web page from my friend who shared with me about this website and at the moment this time I am

visiting this web page and reading very informative content at this place.

Helpful info. Fortunate me I discovered your site unintentionally, and I’m stunned

why this accident did not took place in advance! I bookmarked it.

I’m impressed, I have to admit. Rarely do I come

across a blog that’s equally educative and engaging, and let me tell

you, you have hit the nail on the head. The issue

is an issue that too few men and women are speaking intelligently

about. I’m very happy that I found this during my search for something concerning this.

I need to to thank you for this good read!! I definitely loved every little

bit of it. I have you saved as a favorite to look at new stuff you

post…

Hi! Do you use Twitter? I’d like to follow you if that would be ok.

I’m absolutely enjoying your blog and look forward to

new posts.

Fastidious respond in return of this question with solid arguments and describing all on the topic of that.

Thanks for every other informative web site. The place else may I get that kind of information written in such a perfect manner?

I’ve a project that I am simply now working on, and I’ve been on the look out for such info.

You have made some really good points there.

I looked on the web to find out more about the issue

and found most individuals will go along with your views

on this website.

I am truly glad to read this blog posts which includes plenty of helpful

information, thanks for providing these information.

We’re a group of volunteers and starting a new scheme in our community.

Your site provided us with valuable info to work on. You’ve done a formidable job and our whole community will be

thankful to you.

Admiring the persistence you put into your site and in depth information you provide.

It’s nice to come across a blog every once in a while that isn’t the same out of date rehashed material.

Great read! I’ve bookmarked your site and I’m including your RSS feeds to my Google account.

Heya i am for the first time here. I came across this board and

I in finding It really useful & it helped me out a lot.

I hope to provide something back and help others like you helped me.

I’m not that much of a internet reader to be honest but your blogs really nice, keep it up!

I’ll go ahead and bookmark your site to come back later. Many

thanks

Magnificent beat ! I wish to apprentice while you amend your website, how could i subscribe for a blog website?

The account helped me a acceptable deal. I had been tiny bit acquainted of this your broadcast provided bright clear idea

I think the admin of this web site is actually working hard

in support of his web site, since here every stuff is quality based data.

Hello, i think that i saw you visited my website thus i came

to “return the favor”.I am trying to find things to enhance my

web site!I suppose its ok to use some of your ideas!!

This paragraph will help the internet visitors for setting up

new blog or even a weblog from start to end.

Thanks for another magnificent article. The place else may just anyone

get that type of info in such a perfect approach of writing?

I’ve a presentation subsequent week, and I am on the look for

such info.

Hello! I’ve been reading your site for a long time now and finally

got the courage to go ahead and give you a shout out from Huffman Tx!

Just wanted to mention keep up the good job!

Quality articles or reviews is the secret to attract the people to go to see the website, that’s what this website is providing.

Howdy! Would you mind if I share your blog with my zynga group?

There’s a lot of people that I think would really enjoy your

content. Please let me know. Many thanks

Post writing is also a excitement, if you be acquainted with afterward you can write otherwise it

is complex to write.

Hey There. I found your blog using msn. That is an extremely well written article.

I’ll make sure to bookmark it and come back to learn more of your helpful info.

Thanks for the post. I will certainly comeback.

Hello there! This is my 1st comment here so I just wanted to give a quick shout out and tell you I genuinely enjoy reading your articles.

Can you suggest any other blogs/websites/forums that go over the same subjects?

Thank you!

Why viewers still make use of to read news papers when in this technological world everything is available on web?

You really make it appear really easy along with your presentation however I to find this matter to be actually something which I think I might never understand.

It sort of feels too complicated and very wide for me.

I am having a look forward on your subsequent submit, I’ll try to get the

dangle of it!

What’s Taking place i’m new to this, I stumbled upon this I’ve discovered It positively helpful and it

has helped me out loads. I’m hoping to give a contribution & help different customers like

its helped me. Great job.

Great blog here! Also your site loads up very fast!

What web host are you using? Can I get your affiliate link to your host?

I wish my web site loaded up as fast as yours

lol

Good article. I am going through a few of these issues as well..

Greetings! Very helpful advice within this article! It is the little changes which will make the largest

changes. Thanks for sharing!

I really like reading an article that will make people think.

Also, many thanks for allowing for me to comment!

I am truly grateful to the holder of this site who has shared this great article at at this time.

Very good site you have here but I was wondering if you knew of any discussion boards that cover

the same topics talked about here? I’d really like to be a part of group

where I can get feedback from other knowledgeable individuals that share the same interest.

If you have any suggestions, please let me know. Appreciate

it!

Nice weblog here! Also your site so much up

very fast! What host are you using? Can I am getting your associate link for your host?

I desire my web site loaded up as quickly as yours lol

You really make it appear so easy along with your presentation however I

find this matter to be really something that I feel I’d never understand.

It kind of feels too complex and extremely extensive for me.

I am looking forward to your next post, I will try to get the grasp

of it!

It’s truly a nice and useful piece of information. I’m glad that you just shared this useful info with us.

Please keep us up to date like this. Thanks

for sharing.

Hello there! I know this is kinda off topic nevertheless

I’d figured I’d ask. Would you be interested in trading links or maybe guest authoring a

blog article or vice-versa? My blog discusses a lot of

the same subjects as yours and I believe we could greatly benefit from each other.

If you are interested feel free to send me an e-mail.

I look forward to hearing from you! Terrific blog by the

way!

WOW just what I was looking for. Came here by searching for

bokep bocil

Its like you read my mind! You appear to know a lot

about this, like you wrote the book in it or something.

I think that you could do with some pics to drive the message home a bit,

but instead of that, this is great blog. A fantastic

read. I will certainly be back.

Hello there, You have done an excellent job. I’ll certainly

digg it and personally suggest to my friends. I am sure they will be benefited from this website.

Hi there, I log on to your new stuff like every week.

Your humoristic style is witty, keep up the good work!

I do not even know how I ended up here, but I thought this post

was great. I don’t know who you are but definitely you

are going to a famous blogger if you are not already 😉 Cheers!

Hello there, You’ve done a fantastic job. I will definitely

digg it and personally recommend to my friends.

I am confident they will be benefited from this website.

Ahaa, its good dialogue regarding this piece of writing here at this website,

I have read all that, so at this time me also commenting here.

These are actually great ideas in about blogging. You have

touched some nice points here. Any way keep up wrinting.

I’m not sure where you are getting your info, but good topic.

I needs to spend some time learning more or understanding more.

Thanks for magnificent information I was looking for this info for my mission.

Hello! I could have sworn I’ve been to this website before but after browsing

through some of the post I realized it’s new to me.

Anyways, I’m definitely happy I found it and I’ll be book-marking and checking back frequently!

I’m really enjoying the design and layout of your

website. It’s a very easy on the eyes which makes it much more pleasant for

me to come here and visit more often. Did you hire out a

developer to create your theme? Outstanding work!

Magnificent beat ! I would like to apprentice while you amend your web site, how can i subscribe for a blog web site?

The account helped me a acceptable deal. I had been tiny bit acquainted of this your broadcast provided

bright clear concept

This design is spectacular! You most certainly know how to keep a

reader entertained. Between your wit and your videos, I

was almost moved to start my own blog (well, almost…HaHa!) Excellent job.

I really enjoyed what you had to say, and more than that,

how you presented it. Too cool!

Hi there, I enjoy reading through your article post. I

wanted to write a little comment to support you.

It’s going to be end of mine day, but before ending I am reading this impressive

post to improve my experience.

Hello! Would you mind if I share your blog with my myspace

group? There’s a lot of folks that I think would really enjoy

your content. Please let me know. Thanks

Hey would you mind letting me know which hosting company you’re utilizing?

I’ve loaded your blog in 3 completely different browsers and

I must say this blog loads a lot faster then most. Can you

recommend a good internet hosting provider at a reasonable price?

Kudos, I appreciate it!

Everything is very open with a very clear explanation of the challenges.

It was definitely informative. Your site is extremely helpful.

Thanks for sharing!

I always spent my half an hour to read this blog’s articles

or reviews every day along with a mug of coffee.

Wow, wonderful blog structure! How lengthy have you been blogging

for? you made blogging look easy. The full glance of your website is great, as well

as the content!

I constantly spent my half an hour to read this blog’s content every day

along with a mug of coffee.

I just like the helpful information you supply for your articles.

I will bookmark your blog and test once more here frequently.

I’m moderately certain I’ll learn many new stuff proper here!

Best of luck for the next!

I do not even know the way I ended up here, but I believed this publish was great.

I do not understand who you are but definitely you are going to a well-known blogger if you happen to aren’t already.

Cheers!

Heya! I just wanted to ask if you ever have any problems with hackers?

My last blog (wordpress) was hacked and I ended up losing

months of hard work due to no backup. Do you have any methods to prevent

hackers?

Great site you’ve got here.. It’s difficult to find excellent writing like yours

these days. I really appreciate people like you!

Take care!!

Great blog! Is your theme custom made or did you download

it from somewhere? A theme like yours with a few simple tweeks

would really make my blog shine. Please let me know where you got your theme.

Thank you

I got this web page from my pal who informed me on the topic of this website and

at the moment this time I am browsing this site and reading very informative content at this time.

Unquestionably believe that which you stated. Your favorite justification seemed to be on the internet the easiest thing to be aware of.

I say to you, I definitely get irked while people consider worries that they plainly

do not know about. You managed to hit the nail upon the top and

also defined out the whole thing without having

side effect , people can take a signal. Will probably be back to get more.

Thanks

Hello there! Do you know if they make any plugins to safeguard against hackers?

I’m kinda paranoid about losing everything I’ve worked hard on. Any recommendations?

This article is in fact a fastidious one it helps new net visitors, who are wishing for blogging.

I was wondering if you ever considered changing the structure of your website?

Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect with it better.

Youve got an awful lot of text for only having 1

or two pictures. Maybe you could space it out better?

Wonderful goods from you, man. I’ve understand your

stuff previous to and you’re just extremely magnificent.

I really like what you’ve acquired here, really like what

you’re stating and the way in which you say it. You make it

enjoyable and you still care for to keep it sensible. I can’t wait to read much more from you.

This is really a terrific website.

It’s difficult to find well-informed people about this topic, however,

you seem like you know what you’re talking about!

Thanks

It is in point of fact a nice and helpful piece

of info. I am happy that you just shared this useful info with us.

Please keep us informed like this. Thanks for sharing.

Hey there! I could have sworn I’ve been to this website

before but after reading through some of the post I realized it’s new to me.

Anyways, I’m definitely happy I found it and I’ll be book-marking and checking

back often!

Very good blog! Do you have any tips and hints for aspiring writers?

I’m hoping to start my own site soon but I’m a little lost on everything.

Would you advise starting with a free platform like WordPress or go for a paid option? There are

so many options out there that I’m completely confused ..

Any tips? Thanks a lot!

It is actually a nice and useful piece of information.

I’m glad that you just shared this helpful information with us.

Please keep us up to date like this. Thank you for sharing.

Good day! Do you know if they make any plugins to safeguard against

hackers? I’m kinda paranoid about losing everything I’ve worked hard on. Any tips?

I was curious if you ever thought of changing the page layout of your blog?

Its very well written; I love what youve got to say.

But maybe you could a little more in the way of content so people could connect with it better.

Youve got an awful lot of text for only having 1 or 2 images.

Maybe you could space it out better?

I would like to thank you for the efforts you have put in penning this

website. I am hoping to check out the same high-grade content by

you later on as well. In fact, your creative writing

abilities has inspired me to get my own blog now

😉

I every time spent my half an hour to read this web site’s articles daily along with a mug

of coffee.

Please let me know if you’re looking for a author for your site.

You have some really great posts and I think I would be a good asset.

If you ever want to take some of the load off, I’d really like to write

some material for your blog in exchange for a link back to mine.

Please shoot me an e-mail if interested. Thank you!

I am regular reader, how are you everybody? This paragraph posted at this

web page is truly fastidious.

Hiya! I know this is kinda off topic however I’d figured I’d ask.

Would you be interested in trading links or maybe guest writing a

blog article or vice-versa? My blog addresses a lot of the same subjects as yours and I feel we could greatly benefit from each other.

If you are interested feel free to shoot me an e-mail. I look forward to

hearing from you! Great blog by the way!

What a information of un-ambiguity and preserveness of valuable knowledge concerning

unexpected emotions.

Hello are using WordPress for your blog platform? I’m new to the blog world but I’m trying to get started and create my own. Do you require any coding knowledge to

make your own blog? Any help would be greatly appreciated!

When someone writes an piece of writing he/she keeps the idea of a user in his/her brain that how a

user can be aware of it. Thus that’s why this article is amazing.

Thanks!

Howdy! This is my first visit to your blog!

We are a team of volunteers and starting a new project in a community in the same niche.

Your blog provided us beneficial information to work

on. You have done a extraordinary job!

Wow that was unusual. I just wrote an extremely long comment but after I clicked submit my comment didn’t appear.

Grrrr… well I’m not writing all that over again. Anyway, just wanted to say superb blog!

After looking into a handful of the blog posts on your website,

I seriously like your technique of blogging. I book marked it to my bookmark

website list and will be checking back soon. Take a look at my

website as well and tell me what you think.

Excellent post. Keep writing such kind of information on your page.

Im really impressed by your site.

Hello there, You have done an incredible job. I’ll certainly digg it and for my part recommend

to my friends. I am confident they’ll be benefited from this web site.

Nice post. I was checking constantly this blog and I am impressed!

Extremely useful information particularly the last part 🙂

I care for such information much. I was seeking this particular information for a very long time.

Thank you and good luck.

These are in fact impressive ideas in on the topic

of blogging. You have touched some nice things here. Any way keep up wrinting.

Excellent items from you, man. I have remember your stuff previous to and you are

simply extremely wonderful. I really like what you have acquired right

here, really like what you are stating and the best way by which you say it.

You’re making it enjoyable and you continue to

take care of to stay it sensible. I can’t wait to learn much

more from you. This is actually a terrific web site.

Hey there! This is kind of off topic but I need some

help from an established blog. Is it hard to set up your own blog?

I’m not very techincal but I can figure things

out pretty fast. I’m thinking about creating my own but I’m

not sure where to start. Do you have any ideas or suggestions?

With thanks

When I initially commented I clicked the “Notify me when new comments are added” checkbox

and now each time a comment is added I get several emails with the same comment.

Is there any way you can remove people from that service?

Many thanks!

Piece of writing writing is also a fun, if you be familiar with after that you

can write if not it is difficult to write.

This is really interesting, You are a very skilled blogger.

I’ve joined your rss feed and stay up for in the hunt for extra of your excellent post.

Additionally, I’ve shared your website in my social networks

I think that what you said made a great deal of sense. But, consider this, what if you

wrote a catchier post title? I am not saying your content is not solid., however suppose

you added a headline that makes people desire more?

I mean ACM Sheets; ACP Panel Structure and Properties Explained is kinda plain. You ought to peek at Yahoo’s home page and see how they write news headlines to grab viewers

to open the links. You might add a video or a related picture or two to get readers interested about what you’ve written. In my

opinion, it might bring your website a little bit more interesting.

Hi just wanted to give you a brief heads up and let you

know a few of the pictures aren’t loading properly. I’m not sure why but I think its

a linking issue. I’ve tried it in two different web browsers and both show the same

outcome.

Hello, I enjoy reading all of your article post.

I like to write a little comment to support

you.

I like what you guys are up too. This kind of clever work and coverage!

Keep up the terrific works guys I’ve you guys to my personal blogroll.

It’s actually a nice and helpful piece of information.

I am glad that you shared this useful information with us.

Please keep us up to date like this. Thank you for sharing.

Excellent goods from you, man. I’ve understand your stuff previous to and you

are just too excellent. I really like what you’ve acquired here,

certainly like what you are saying and the way in which you say it.

You make it enjoyable and you still take care of to keep it sensible.

I can’t wait to read far more from you. This is really a

tremendous website.

naturally like your website but you need to test

the spelling on several of your posts. Several of them are rife

with spelling problems and I find it very bothersome to

inform the reality however I will definitely come again again.

I am sure this article has touched all the internet users, its really really pleasant article on building up new webpage.

Thanks for sharing your thoughts. I really appreciate your efforts

and I am waiting for your further post thanks once again.

Very nice post. I just stumbled upon your blog and wanted to say that I have really enjoyed surfing around your blog posts.

After all I will be subscribing on your feed and I am hoping you write again soon!

Wow, that’s what I was searching for, what a stuff!

present here at this webpage, thanks admin of this website.

I am really thankful to the holder of this website who has shared this great piece of writing at at this place.

We’re a group of volunteers and starting a new scheme in our community.

Your website provided us with valuable info to work on. You have done a formidable job and our entire community will be thankful to you.

Hi! This is my first comment here so I just wanted to give a quick shout out and say I genuinely enjoy reading through your

articles. Can you suggest any other blogs/websites/forums

that deal with the same topics? Thanks a

ton!

Hey there! I’ve been following your site for a while now and

finally got the bravery to go ahead and give

you a shout out from Lubbock Texas! Just wanted to tell you keep up the good work!

Hello there! Do you know if they make any plugins to help

with Search Engine Optimization? I’m trying to get my blog to rank for

some targeted keywords but I’m not seeing very good gains. If you know of any please share.

Thank you!

I used to be able to find good advice from your content.

If you desire to obtain a great deal from this piece of writing then you have to apply these techniques to your won blog.

I read this post fully on the topic of the resemblance of latest and previous technologies, it’s

awesome article.

Thank you for the good writeup. It in fact

was a amusement account it. Look advanced to more added agreeable from you!

However, how can we communicate?

An interesting discussion is worth comment.

I do think that you need to write more on this subject matter, it may not be a taboo matter but

usually people don’t talk about these subjects.

To the next! Kind regards!!

I loved as much as you’ll receive carried out right here.

The sketch is attractive, your authored subject matter stylish.

nonetheless, you command get bought an shakiness over that you

wish be delivering the following. unwell unquestionably come more formerly again as

exactly the same nearly very often inside case you shield this hike.

I am genuinely glad to read this web site posts which consists

of plenty of helpful information, thanks for providing these kinds of data.

I seriously love your blog.. Very nice colors & theme.

Did you develop this web site yourself? Please reply back as I’m attempting to create my

very own blog and would love to find out where you got this from

or just what the theme is named. Thanks!

I used to be suggested this blog via my cousin. I’m now not

sure whether this post is written through him as no one else know such unique

about my trouble. You’re incredible! Thank you!

whoah this weblog is magnificent i love studying your posts.

Keep up the good work! You recognize, many individuals are searching around for this info, you

can aid them greatly.

I’m truly enjoying the design and layout of your website.

It’s a very easy on the eyes which makes it much more enjoyable for me to

come here and visit more often. Did you hire out a designer to

create your theme? Excellent work!

Thank you for every other informative web site. Where else may I get that type of information written in such

an ideal means? I have a challenge that I’m just now working on, and I’ve been at the look out for such information.

Thank you for the good writeup. It in fact was a amusement

account it. Look advanced to far added agreeable from you!

However, how can we communicate?

Hello There. I found your blog using msn. This is an extremely well written article.

I’ll make sure to bookmark it and come back to read more

of your useful information. Thanks for the post. I’ll certainly comeback.

Useful info. Lucky me I discovered your site unintentionally,

and I’m shocked why this twist of fate didn’t took place in advance!

I bookmarked it.

Hola! I’ve been following your weblog for a long time now and finally got the courage to go

ahead and give you a shout out from Houston Tx! Just wanted to mention keep up the fantastic job!

You really make it appear so easy with your presentation however I to find this matter

to be actually one thing that I think I’d never

understand. It kind of feels too complicated and extremely wide for me.

I’m taking a look ahead in your next publish, I will try to get the dangle of it!

I am truly grateful to the holder of this site who

has shared this enormous article at at this place.

This piece of writing gives clear idea in support of the new users of blogging, that really how to do blogging

and site-building.

What a data of un-ambiguity and preserveness of precious familiarity on the topic of unexpected emotions.

It’s an amazing post in support of all the internet

users; they will obtain benefit from it I am sure.

I am really inspired with your writing abilities and also with

the structure for your blog. Is this a paid topic or did you customize it your self?

Either way keep up the excellent high quality

writing, it is uncommon to see a great blog like this one nowadays..

Your style is really unique in comparison to other folks I’ve read stuff from.

I appreciate you for posting when you have the opportunity, Guess I’ll just bookmark this blog.

Hi there, I enjoy reading all of your post. I wanted to write a little comment to support you.

Nice blog here! Also your website loads up very fast!

What web host are you using? Can I get your affiliate link to your host?

I wish my site loaded up as quickly as yours lol

Hurrah! In the end I got a blog from where I be capable of genuinely get useful information concerning my study and knowledge.

Incredible! This blog looks just like my old one!

It’s on a totally different subject but it has pretty much the same page

layout and design. Wonderful choice of colors!

Nice weblog here! Also your site a lot up very fast!

What web host are you the usage of? Can I get your associate

link to your host? I want my web site loaded up

as fast as yours lol

Everything is very open with a clear clarification of the issues.

It was definitely informative. Your site is useful.

Thank you for sharing!

I savour, cause I found exactly what I used to be looking for.

You have ended my 4 day long hunt! God Bless you man. Have a

nice day. Bye

Woah! I’m really loving the template/theme of this blog. It’s simple, yet effective.

A lot of times it’s tough to get that “perfect balance” between superb usability and visual appeal.

I must say you have done a excellent job with this. Additionally, the blog loads very fast for me on Firefox.

Excellent Blog!

This is my first time go to see at here and i am really

pleassant to read all at alone place.

I’m gone to inform my little brother, that he should also pay a visit this web

site on regular basis to take updated from most up-to-date reports.

Hello, i think that i saw you visited my weblog so i came to “return the favor”.I’m trying to find things

to improve my site!I suppose its ok to use some of your ideas!!

I’m really impressed along with your writing talents as neatly as

with the format in your blog. Is that this a paid subject or did you

modify it yourself? Either way stay up the nice quality writing, it’s uncommon to look a nice blog like

this one today..

You’ve made some really good points there. I checked on the net for additional information about the issue and found most people will

go along with your views on this website.

This info is priceless. When can I find out more?

What’s up, after reading this amazing article i am too delighted to share

my know-how here with mates.

What i do not realize is in truth how you are not really much more

neatly-appreciated than you might be now. You are very intelligent.

You know therefore significantly with regards to this matter, made me

personally consider it from numerous various angles.

Its like women and men don’t seem to be interested unless it is one thing to

do with Woman gaga! Your personal stuffs excellent. Always maintain it up!

Hello, I do believe your site could be having web browser compatibility issues.

Whenever I look at your web site in Safari, it looks fine however when opening in IE, it’s got some overlapping issues.

I merely wanted to provide you with a quick heads up!

Other than that, excellent blog!

Everything is very open with a precise clarification of the challenges.

It was definitely informative. Your website is extremely helpful.

Thanks for sharing!

I am sure this piece of writing has touched all the internet people, its really really

nice post on building up new webpage.

Everything is very open with a very clear clarification of the challenges.

It was definitely informative. Your website is extremely helpful.

Many thanks for sharing!

Good day! Would you mind if I share your

blog with my twitter group? There’s a lot of people that I think would really enjoy

your content. Please let me know. Thank

you

Hi there! I just wanted to ask if you ever have any problems with hackers?

My last blog (wordpress) was hacked and I ended up

losing months of hard work due to no back up. Do you have any methods to prevent hackers?

Hi, I think your blog might be having browser compatibility issues.

When I look at your blog in Safari, it looks fine but when opening in Internet

Explorer, it has some overlapping. I just wanted to give you a quick heads up!

Other then that, superb blog!

A fascinating discussion is worth comment. I do think that you should publish more on this issue, it

might not be a taboo subject but generally folks don’t discuss

these issues. To the next! Best wishes!!

Admiring the commitment you put into your website and in depth information you present.

It’s great to come across a blog every once in a

while that isn’t the same outdated rehashed information. Excellent read!

I’ve saved your site and I’m including your RSS

feeds to my Google account.

I’m impressed, I must say. Rarely do I encounter a blog that’s

equally educative and interesting, and let me tell you, you have

hit the nail on the head. The issue is an issue that too few folks are speaking intelligently about.

I’m very happy that I came across this during my

search for something relating to this.

magnificent put up, very informative. I’m wondering why the other

experts of this sector do not realize this. You should continue your writing.

I’m confident, you’ve a great readers’ base already!

I think the admin of this website is in fact working hard in support of his web

site, as here every material is quality based material.

Howdy! I could have sworn I’ve been to this website before but after

browsing through some of the articles I realized it’s new to me.

Regardless, I’m certainly delighted I discovered it

and I’ll be bookmarking it and checking back frequently!

Hi there would you mind letting me know which web host you’re working with?

I’ve loaded your blog in 3 different web browsers and I must say this blog loads a lot

faster then most. Can you suggest a good web hosting provider at a reasonable price?

Thanks a lot, I appreciate it!

You ought to take part in a contest for one of the greatest sites on the

internet. I most certainly will recommend this web site!

Wonderful blog! I found it while browsing on Yahoo News.

Do you have any tips on how to get listed in Yahoo

News? I’ve been trying for a while but I

never seem to get there! Thank you

Hello there, just became aware of your blog through Google, and found

that it’s really informative. I am going to watch out for brussels.

I will be grateful if you continue this in future. Numerous people will be benefited from your writing.

Cheers!

Its like you read my thoughts! You seem to know a lot about this, such

as you wrote the e book in it or something. I feel that you could do with a few

p.c. to drive the message house a bit, however other than that, that is magnificent blog.

A fantastic read. I’ll definitely be back.

Aw, this was an extremely nice post. Taking a few minutes and actual effort to

make a good article… but what can I say… I hesitate a lot

and don’t seem to get nearly anything done.

Your style is really unique in comparison to other

folks I’ve read stuff from. Thanks for posting when you have the opportunity,

Guess I’ll just book mark this site.

Hello there, I discovered your website by means of Google while looking for a comparable subject, your web site got here up, it seems

great. I have bookmarked it in my google bookmarks.

Hi there, just turned into alert to your blog via Google,

and found that it’s truly informative. I’m gonna be careful for brussels.

I will appreciate for those who proceed this in future.

Lots of folks will probably be benefited from your writing.

Cheers!

An outstanding share! I have just forwarded this onto a friend who was doing a little homework

on this. And he actually ordered me breakfast due to the fact that I stumbled

upon it for him… lol. So let me reword this….

Thank YOU for the meal!! But yeah, thanks for spending time to talk about this topic

here on your blog.

Someone essentially assist to make severely posts I’d

state. This is the first time I frequented your web page and up to now?

I surprised with the research you made to create this actual submit incredible.

Great job!

I will right away take hold of your rss as I can’t find your email subscription link or newsletter service.

Do you have any? Kindly allow me understand so that I may

subscribe. Thanks.

What’s up mates, its impressive piece of writing regarding teachingand completely explained, keep it up

all the time.

I am really inspired with your writing skills and also with the format in your blog.

Is this a paid subject or did you modify it your self?

Either way stay up the excellent quality writing, it is rare to look a nice weblog like this one today..

Hello there! Do you know if they make any plugins to help with SEO?

I’m trying to get my blog to rank for some targeted keywords but I’m

not seeing very good gains. If you know of any please share.

Many thanks!

What’s up friends, its fantastic article regarding educationand entirely defined,

keep it up all the time.

I’m truly enjoying the design and layout of your blog.

It’s a very easy on the eyes which makes it much more enjoyable for me to come here and

visit more often. Did you hire out a designer to create

your theme? Exceptional work!

I think this is one of the most vital information for me.

And i’m glad reading your article. But wanna remark on some

general things, The website style is perfect, the articles is really

excellent : D. Good job, cheers

Quality articles is the important to invite the visitors to pay a quick visit the web site, that’s

what this site is providing.

It is actually a nice and useful piece of information. I’m happy

that you just shared this helpful info with us. Please keep us up to date

like this. Thank you for sharing.

Hi there, I do believe your web site may be having web browser compatibility problems.

Whenever I take a look at your web site in Safari, it looks fine

however, when opening in Internet Explorer, it’s got some

overlapping issues. I just wanted to provide you with a quick heads up!

Apart from that, fantastic website!

Hey there just wanted to give you a quick heads up. The words in your article seem to

be running off the screen in Safari. I’m not sure if this is a formatting issue or something to do with web

browser compatibility but I thought I’d post to let you know.

The design look great though! Hope you get the problem fixed soon. Kudos

Definitely believe that which you said. Your favorite reason appeared to be on the net the simplest

thing to be aware of. I say to you, I certainly get

irked while people consider worries that they plainly don’t know about.

You managed to hit the nail upon the top and defined out the whole thing without having side-effects

, people can take a signal. Will likely be back to get more.

Thanks

My coder is trying to persuade me to move to .net

from PHP. I have always disliked the idea because of the expenses.

But he’s tryiong none the less. I’ve been using Movable-type on several websites for

about a year and am worried about switching to another

platform. I have heard great things about blogengine.net.

Is there a way I can transfer all my wordpress content into it?

Any help would be greatly appreciated!

Please let me know if you’re looking for a article author for your blog.

You have some really great articles and I think I would be a good asset.

If you ever want to take some of the load off, I’d absolutely love to write some articles for your blog in exchange for a link back to mine.

Please send me an e-mail if interested. Cheers!

Hello, i think that i noticed you visited my web site so i got here to go back the desire?.I am attempting to in finding issues to improve

my web site!I guess its ok to use some of your concepts!!

What’s up friends, nice article and pleasant urging commented here, I am

genuinely enjoying by these.

I every time spent my half an hour to read this weblog’s articles every day along with a

cup of coffee.

I do not know whether it’s just me or if perhaps everybody else experiencing issues with your site.

It seems like some of the written text on your posts are running off

the screen. Can someone else please comment and let me know if

this is happening to them as well? This could be a issue with my internet browser because I’ve had this happen before.

Thanks

fantastic put up, very informative. I’m wondering why the other specialists of this sector do not

notice this. You should continue your writing. I am sure, you’ve a

great readers’ base already!

WOW just what I was looking for. Came here by searching for forumbb21

I am really enjoying the theme/design of your

website. Do you ever run into any internet browser compatibility issues?

A handful of my blog readers have complained about my blog

not working correctly in Explorer but looks great in Opera.

Do you have any advice to help fix this problem?

Hi there, just became alert to your blog through Google,

and found that it’s really informative. I’m going to

watch out for brussels. I will appreciate if you continue this in future.

Numerous people will be benefited from your writing.

Cheers!

I’m not sure where you are getting your information, but

good topic. I needs to spend some time learning more or understanding more.

Thanks for magnificent information I was looking for this information for my mission.

Excellent web site you have here.. It’s difficult to find

excellent writing like yours nowadays. I honestly appreciate individuals like you!

Take care!!

What’s up, I wish for to subscribe for this website to obtain most up-to-date updates,

so where can i do it please assist.

Hmm is anyone else encountering problems with the pictures on this

blog loading? I’m trying to find out if its a problem on my end or if it’s

the blog. Any suggestions would be greatly appreciated.

Great weblog right here! Also your web site lots up fast!

What host are you the usage of? Can I am getting your affiliate hyperlink for

your host? I wish my site loaded up as fast as yours lol

Its like you read my mind! You appear to know so

much about this, like you wrote the book in it or something.

I think that you can do with some pics to drive

the message home a bit, but other than that, this is excellent blog.

A fantastic read. I’ll certainly be back.

Wow, this paragraph is nice, my sister is analyzing such

things, thus I am going to convey her.

Please let me know if you’re looking for a article author for your blog.

You have some really great articles and I think I would be a good asset.

If you ever want to take some of the load off, I’d absolutely love to write some content for your blog in exchange for

a link back to mine. Please blast me an email if interested.

Thank you!

You’ve made some good points there. I looked on the net to find out more about the issue and found most individuals will go

along with your views on this website.

I just like the helpful information you supply to your articles.

I will bookmark your weblog and test again here regularly.

I am fairly sure I will be told many new stuff proper here!

Good luck for the next!

Wow, this piece of writing is pleasant, my sister is

analyzing these things, therefore I am going

to let know her.

My brother suggested I might like this web site.

He was totally right. This post actually made my day.

You can not imagine simply how much time I had spent for this info!

Thanks!

Hi there! I could have sworn I’ve been to this site before but after checking through some

of the post I realized it’s new to me. Anyways, I’m definitely glad I found it and I’ll be bookmarking and checking back often!

Woah! I’m really digging the template/theme of this blog.

It’s simple, yet effective. A lot of times it’s very hard to get that “perfect balance” between usability

and appearance. I must say you’ve done a fantastic job

with this. In addition, the blog loads very fast for me on Internet explorer.

Excellent Blog!

Have you ever considered about adding a little bit more

than just your articles? I mean, what you say is important and all.

However think of if you added some great pictures or videos to give your posts more, “pop”!

Your content is excellent but with pics and videos, this blog could certainly

be one of the best in its niche. Good blog!

Everything said made a ton of sense. But, consider this, suppose you were

to write a killer headline? I am not suggesting your content is not solid, however suppose you added a headline

that grabbed folk’s attention? I mean ACM Sheets; ACP Panel Structure and Properties Explained

is a little boring. You might look at Yahoo’s home

page and note how they create post titles to grab viewers to click.

You might add a related video or a pic or two to grab readers excited

about what you’ve written. Just my opinion, it might make your posts a little bit more interesting.

I am regular reader, how are you everybody? This paragraph posted at this web site is really pleasant.

Wonderful goods from you, man. I’ve remember your stuff

previous to and you’re just too excellent. I actually like what you have bought right here,

really like what you’re saying and the way in which wherein you say it.

You are making it enjoyable and you still care for to stay it wise.

I cant wait to learn far more from you. This is really a wonderful

website.

You actually make it seem so easy with your presentation but I find this topic to

be actually something that I think I would never understand.

It seems too complicated and extremely broad for me. I’m looking forward for your next post, I’ll try to get the hang of

it!

I am now not positive where you’re getting your info, however good topic.

I needs to spend some time learning much more or understanding more.

Thank you for excellent information I used to be in search

of this info for my mission.

Thanks for finally talking about > ACM Sheets; ACP

Panel Structure and Properties Explained < Liked it!

Attractive component to content. I simply stumbled upon your weblog and in accession capital to assert that I get actually loved account your blog posts.

Any way I’ll be subscribing for your augment or even I achievement you get admission to persistently quickly.

Excellent post. I was checking continuously this blog and I am impressed!

Very useful information particularly the last part 🙂 I care for such info

a lot. I was seeking this particular information for a very long time.

Thank you and best of luck.

Hi there to every body, it’s my first visit of this weblog; this

website contains awesome and actually good data in favor of readers.

Excellent, what a website it is! This website gives valuable facts to us, keep it up.

After I initially commented I appear to have clicked on the

-Notify me when new comments are added- checkbox and now whenever a comment

is added I recieve four emails with the exact same comment.

Perhaps there is an easy method you are able to remove me from that service?

Kudos!

If you are going for most excellent contents like myself, just go to see this web page daily as it presents quality contents, thanks

An outstanding share! I have just forwarded this onto a colleague who has been conducting a little homework

on this. And he in fact ordered me dinner due to the fact that

I found it for him… lol. So let me reword this…. Thanks for the

meal!! But yeah, thanks for spending time to talk about this subject here on your internet site.

Hi! I understand this is kind of off-topic but

I had to ask. Does building a well-established blog like yours take a lot

of work? I’m brand new to blogging however I do write in my journal every day.

I’d like to start a blog so I will be able to share my personal experience and feelings online.

Please let me know if you have any suggestions or tips for new

aspiring bloggers. Appreciate it!

Heya i’m for the first time here. I found this board and

I find It truly useful & it helped me out much. I hope to give something back and help

others like you helped me.

This is really interesting, You are a very

skilled blogger. I have joined your feed and look forward to seeking more of your magnificent post.

Also, I’ve shared your site in my social networks!

I think everything typed was actually very reasonable.

However, what about this? suppose you added a

little information? I ain’t saying your information isn’t solid, but

suppose you added something to maybe get folk’s attention? I mean ACM Sheets; ACP Panel Structure and Properties Explained is a little plain. You

should peek at Yahoo’s home page and note how they write post headlines

to grab people interested. You might try adding a video or a picture or two to get readers excited about what you’ve

written. In my opinion, it could bring your

posts a little bit more interesting.

It’s genuinely very difficult in this full of activity life to listen news on TV, thus I simply use

the web for that reason, and get the most recent news.

For most recent news you have to pay a visit world-wide-web and on web I

found this website as a finest web page for latest

updates.

I’m gone to tell my little brother, that he should also pay

a quick visit this webpage on regular basis to get updated from most recent news update.

Hi there, I discovered your blog by the use of Google even as looking

for a comparable matter, your web site got here up, it

appears to be like good. I have bookmarked it in my

google bookmarks.

Hi there, just was alert to your blog via Google, and found

that it is truly informative. I’m going to watch out for brussels.

I will be grateful when you continue this in future.

A lot of other folks can be benefited from your writing. Cheers!

I do not even know the way I stopped up here,

but I believed this publish was good. I don’t recognize who you’re but definitely you’re going to a famous blogger for those who aren’t already.

Cheers!

Heya! I understand this is kind of off-topic but I had to ask.

Does running a well-established website like yours require a large amount

of work? I’m completely new to running a blog but I do write in my

journal on a daily basis. I’d like to start a blog so I will

be able to share my experience and views online. Please let me know if

you have any kind of suggestions or tips for brand new aspiring blog owners.

Thankyou!

Appreciate the recommendation. Will try it out.

Now I am ready to do my breakfast, once having

my breakfast coming over again to read further news.

Thanks for your marvelous posting! I actually enjoyed reading it, you can be a great

author.I will ensure that I bookmark your blog

and definitely will come back later on. I want

to encourage continue your great work, have a nice evening!

bookmarked!!, I really like your site!

Can you tell us more about this? I’d love to find out some

additional information.

Hey There. I discovered your weblog using msn. This is an extremely well

written article. I’ll make sure to bookmark it and come back to read more of your helpful info.

Thank you for the post. I will certainly return.

hey there and thank you for your information – I have certainly picked up

anything new from right here. I did however expertise a few technical issues

using this website, since I experienced to reload the web site many times previous to I could get

it to load properly. I had been wondering if your web hosting is OK?

Not that I am complaining, but slow loading instances times will

sometimes affect your placement in google and could damage your

high quality score if ads and marketing with Adwords. Well

I’m adding this RSS to my email and can look out for a lot more

of your respective fascinating content. Make sure you update this

again soon.

Excellent website. A lot of useful information here.

I am sending it to a few buddies ans also sharing in delicious.

And of course, thanks on your sweat!

Heya! I just wanted to ask if you ever have any issues with hackers?

My last blog (wordpress) was hacked and I ended up losing months of hard work due to

no data backup. Do you have any solutions to stop hackers?

This is a topic that is near to my heart… Thank you!

Exactly where are your contact details though?

Keep on working, great job!

I’m impressed, I have to admit. Rarely do I encounter a blog that’s both educative and

engaging, and let me tell you, you have hit the nail

on the head. The problem is something that too few

folks are speaking intelligently about. Now i’m very happy that

I came across this in my search for something relating

to this.

This is a topic that is close to my heart… Thank you! Where are

your contact details though?

Wow, awesome weblog layout! How lengthy have

you been running a blog for? you make running a blog glance easy.

The whole glance of your web site is magnificent, let alone the content!

Hi! This post couldn’t be written any better!

Reading this post reminds me of my previous room mate! He always kept chatting about this.

I will forward this article to him. Pretty sure he will have a good read.

Thanks for sharing!

My brother suggested I might like this web site. He was entirely right.

This post actually made my day. You can not imagine just how much time I had spent for this info!

Thanks!

Piece of writing writing is also a excitement, if you know afterward

you can write otherwise it is difficult to write.

What i do not understood is in truth how you are no

longer actually much more well-liked than you may be right now.

You are very intelligent. You know thus considerably in the case of this subject,

produced me personally imagine it from so many various angles.

Its like women and men are not involved until it’s one thing to accomplish with Woman gaga!

Your own stuffs nice. All the time care for it up!

I seriously love your blog.. Great colors & theme. Did

you build this web site yourself? Please reply back as I’m planning to create my own website

and would love to find out where you got this

from or just what the theme is named. Kudos!

Normally I do not read post on blogs, however I would like to say that this write-up very pressured

me to try and do so! Your writing style has been amazed me.

Thanks, quite nice article.

We are a group of volunteers and starting a new scheme in our

community. Your website offered us with valuable

information to work on. You’ve done a formidable job and our whole community

will be thankful to you.

Thankfulness to my father who informed me on the topic

of this web site, this website is really amazing.

Wow, that’s what I was seeking for, what a data! present here at this webpage,

thanks admin of this web page.

Excellent way of explaining, and fastidious paragraph

to obtain facts about my presentation focus, which i am going to

convey in institution of higher education.

I loved as much as you’ll receive carried out right here. The

sketch is attractive, your authored subject matter stylish.

nonetheless, you command get bought an impatience over that you wish be delivering the following.

unwell unquestionably come further formerly again since exactly the same nearly a lot often inside case

you shield this hike.

I always spent my half an hour to read this weblog’s articles daily along with a cup of coffee.

Great beat ! I wish to apprentice even as you amend your website, how can i subscribe for a blog

web site? The account aided me a applicable deal. I were tiny bit familiar of this your broadcast provided brilliant

transparent concept

Hello, just wanted to tell you, I enjoyed this blog post.

It was practical. Keep on posting!

Look at my site: vpn special coupon

Yesterday, while I was at work, my cousin stole my apple

ipad and tested to see if it can survive a thirty

foot drop, just so she can be a youtube sensation. My apple ipad is now broken and she has 83 views.

I know this is entirely off topic but I had

to share it with someone!

my blog post; vpn 2024

Appreciate this post. Will try it out.

Also visit my page: vpn 2024

Hi, Neat post. There’s a problem together with your site in internet explorer, could test this?

IE still is the marketplace leader and a big portion of folks will pass over your great writing because of this problem.

Also visit my blog; vpn coupon 2024

Thanks for the marvelous posting! I quite enjoyed reading it,

you might be a great author. I will make certain to

bookmark your blog and will eventually come back later in life.

I want to encourage that you continue your great

posts, have a nice morning!

Here is my webpage vpn special coupon code 2024

Wow, superb weblog layout! How long have you been blogging for?

you make running a blog look easy. The entire look of your site is wonderful, as neatly as the

content!

My web-site – vpn special coupon code 2024

I think this is one of the most vital information for me.

And i am glad reading your article. But should remark on few general things,

The website style is ideal, the articles is really great :

D. Good job, cheers

my web site vpn special coupon code 2024

My spouse and I stumbled over here coming from a different website and thought I

should check things out. I like what I see so now i’m following you.

Look forward facebook vs eharmony to find love online exploring your web

page yet again.

Hi there this is kind of of off topic but I was wanting to know

if blogs use WYSIWYG editors or if you have to manually eharmony special coupon code 2024 with HTML.

I’m starting a blog soon but have no coding skills so I wanted

to get advice from someone with experience. Any help would be enormously appreciated!

Nice weblog right here! Additionally your website lots up very

fast! What web host are you using? Can I get your affiliate link

to your host? I want my website loaded up as fast as yours lol

My page … nordvpn special coupon code 2024

Nice weblog here! Additionally your website loads up very fast!

What web host are you the usage of? Can I am getting your associate

hyperlink for your host? I desire my site loaded up as fast as yours

lol

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Porn site

Thank you so much for sharing this wonderful post with us.

Thank you so much for sharing this wonderful post with us.

Thank you for sharing indeed great looking !

I would have met my new finest pal.

2008 TD Banknorth Commerce Bancorp TD Bank, N.A.

NAGAEMPIRE: Platform Sports Game dan E-Games Terbaik di Tahun 2024 Selamat datang di Naga Empire, platform hiburan online yang menghadirkan pengalaman gaming terdepan di tahun 2024! Kami bangga menawarkan sports game, permainan kartu, dan berbagai fitur unggulan yang dirancang untuk memberikan Anda kesenangan dan keuntungan maksimal. Keunggulan Pendaftaran dengan E-Wallet dan QRISKami memprioritaskan kemudahan dan kecepatan dalam pengalaman bermain Anda: Pendaftaran dengan E-Wallet: Daftarkan akun Anda dengan mudah menggunakan e-wallet favorit. Proses pendaftaran sangat cepat, memungkinkan Anda langsung memulai petualangan gaming tanpa hambatan.QRIS Auto Proses dalam 1 Detik: Transaksi Anda diproses instan hanya dalam 1 detik dengan teknologi QRIS, memastikan pembayaran dan deposit berjalan lancar tanpa gangguan.Sports Game dan Permainan Kartu Terbaik di Tahun 2024Naga Empire menawarkan berbagai pilihan game menarik: Sports Game Terlengkap: Dari taruhan olahraga hingga fantasy sports, kami menyediakan sensasi taruhan olahraga dengan kualitas terbaik.Kartu Terbaik di 2024: Nikmati permainan kartu klasik hingga variasi modern dengan grafis yang menakjubkan, memberikan pengalaman bermain yang tak terlupakan.Permainan Terlengkap dan Toto TerlengkapKami memiliki koleksi permainan yang sangat beragam: Permainan Terlengkap: Temukan berbagai pilihan permainan seperti slot mesin, kasino, hingga permainan berbasis keterampilan, semua tersedia di Naga Empire.Toto Terlengkap: Layanan Toto Online kami menawarkan pilihan taruhan yang lengkap dengan odds yang kompetitif, memberikan pengalaman taruhan yang optimal.Bonus Melimpah dan Turnover TerendahBonus Melimpah: Dapatkan bonus mulai dari bonus selamat datang, bonus setoran, hingga promosi eksklusif. Kami selalu memberikan nilai lebih pada setiap taruhan Anda.Turnover Terendah: Dengan turnover rendah, Anda dapat meraih kemenangan lebih mudah dan meningkatkan keuntungan dari setiap permainan.Naga Empire adalah tempat yang tepat bagi Anda yang mencari pengalaman gaming terbaik di tahun 2024. Bergabunglah sekarang dan rasakan sensasi kemenangan di platform yang paling komprehensif!

Today, I went to the beachfront with my kids. I found a sea shell and gave it to my 4 year old daughter and said «You can hear the ocean if you put this to your ear.» She placed the shell to her ear and screamed. There was a hermit crab inside and it pinched her ear. She never wants to go back! LoL I know this is completely off topic but I had to tell someone!

https://iziswaps.site/

Pretty nice post. I just stumbled upon your blog and wished to say that I have truly enjoyed browsing your blog posts. After all I will be subscribing to your feed and I hope you write again soon!

https://iziswaps.site/

https://iziswaps.site/

In a world where trustworthy information is more crucial than ever, your dedication to research and the provision of reliable content is truly commendable. Your commitment to accuracy and transparency shines through in every post. Thank you for being a beacon of reliability in the online realm.

Its like you read my mind! You seem to know so much about this, like you wrote the book in it or something. I think that you can do with a few pics to drive the message home a little bit, but instead of that, this is magnificent blog. An excellent read. I will definitely be back.

The Silver Hawk was powered by the outdated reliable L-head six as normal, with normally aspirated 210- and 225-horsepower variations of the 289 obtainable at extra price.

The information shared is of top quality which has to get appreciated at all levels. Well done…

https://g4u6a.upcloudobjects.com/catering-4/innovative-event-catering.html

Everything is very open with a clear clarification of the issues. It was really informative. Your site is extremely helpful. Many thanks for sharing!

Hello, the product images on your website are very high quality and reflect the real appearance of the products. This allows me to better understand the products.

Scam

Porn site

http://www.fiverr.com/s/Eg2Y0G9

http://www.fiverr.com/s/Eg2Y0G9